Five Major Trends in the Future Development of the Industrial Robot Market

Share

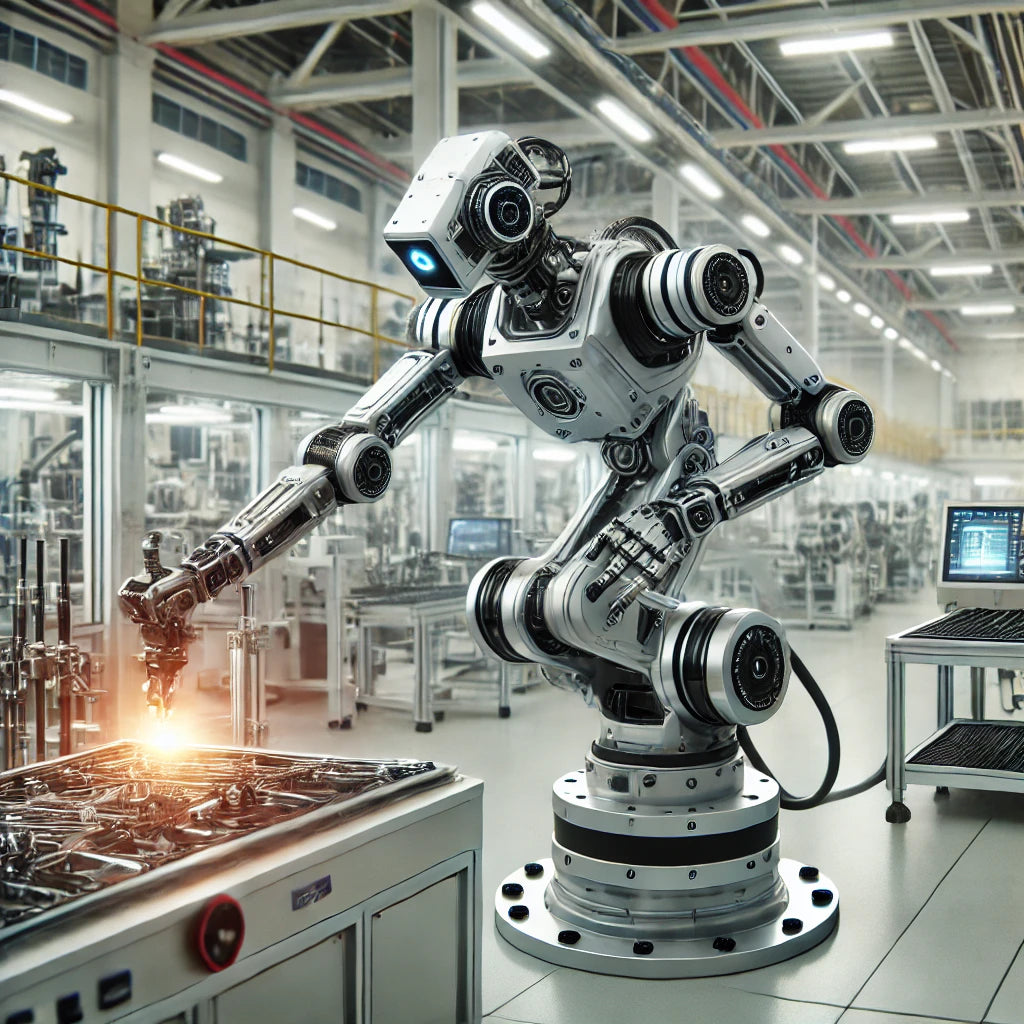

Five trends indicate a future where industrial robots become increasingly intelligent, sustainable, diversified, widely adopted, and collaborative, driving significant advancements in manufacturing and other industries.

-

Intelligent Industry Powered by Artificial Intelligence

- As industrial robot technology advances, AI-driven robots will play a key role in enabling smart manufacturing. These robots will not only perform complex tasks but also handle simultaneous operations like production and data collection, allowing for better evaluation and optimization of processes. Additionally, AI robots with self-detection and repair capabilities will emerge, reducing downtime and improving overall efficiency.

-

Emphasis on Environmental Sustainability

- With increasing global focus on environmental protection, companies are integrating sustainability into their operations. Industrial robots help by enhancing production accuracy, reducing waste from manual errors, and optimizing processes to improve energy efficiency. This will lead to lower carbon emissions and more eco-friendly manufacturing practices.

-

Diversified and Advanced Industrial Robot Technology

- The future of industrial robotics will see the development of more flexible and adaptable robots tailored to meet the specific needs of various industries. These robots will incorporate cutting-edge materials and technologies, becoming lighter, more agile, and aligned with modern streamlined designs. This diversification will enable companies to achieve production goals at lower costs, boosting profit margins.

-

Expansion of Robot Applications Across Industries

- As robot technology matures, its adoption will spread beyond traditional industrial markets into new sectors such as food and beverage, plastics, and more. The COVID-19 pandemic accelerated this trend, with robots being used for tasks like contactless order taking and delivery in restaurants. In the plastics industry, robots are now employed for remote monitoring and quality control, highlighting their growing role in diverse market segments.

-

Human-Machine Collaboration

- The collaboration between humans and robots will enhance production efficiency and flexibility. Industrial robots will take over hazardous tasks, reducing the risk of workplace injuries and creating safer environments. Meanwhile, robots will assist with repetitive tasks, allowing human workers to focus on more strategic roles, ultimately boosting productivity and innovation within companies.